2023-10-14

2023-10-14

Summary:

1. Development environment: favorable policies and economic growth, the industry has broad prospects for development

The plastics industry is one of the pillar industries of my country's light industry and is closely related to my country's national economy. In order to improve the quality and efficiency of the development of the raw material industry, promote the green, sustainable and high-quality development of the plastics processing industry, achieve collaborative innovation in the industrial chain, participate in the domestic and international dual cycles at a higher level, and accelerate the pace of the industry from large to strong, in recent years the country has successively A number of policies have been issued to support the development of the domestic injection molding products industry. As the trend of economic development in the future remains unchanged, social consumption will continue to upgrade, which will provide a good development environment for my country's injection molded products industry, and at the same time drive the application fields of injection molded products such as agriculture, fishery, packaging, transportation, electrical, chemical industry, The development of industries such as construction, aviation, national defense, medical equipment, and daily cosmetics has driven the continued growth in demand for injection molded products, providing broad development prospects for my country's injection molded products industry.

2. Development status: The rapid development of the downstream field has driven the continued expansion of the market size of injection molded products.

At present, the domestic injection molding products industry is in a stage of rapid development. The application scope of injection molding products covers real estate, automobiles, household appliances, packaging, consumer electronics, medical equipment and other fields. The huge downstream industry provides strong support for the development of my country's injection molding products industry. Benefiting from the development and growth of real estate, automobiles and home appliances, packaging, consumer electronics, medical equipment and other industries, the market demand for injection molded products has grown steadily. At the same time, due to further innovative breakthroughs in the performance of domestic injection molded products, the market penetration rate of injection molded products continues to increase, and they have begun to be applied to advanced emerging industries such as aerospace, new energy, and smart homes. The market space for my country's injection molded products continues to expand.

3. Market structure: The industry market structure is fragmented, and the operating situation of key enterprises is improving.

Judging from the distribution of the market competition pattern, the current market pattern of my country's injection molding products industry is fragmented, the industry concentration is extremely low, there is no industry leader yet, and the competition among enterprises is fierce. Calculated based on the income caliber of injection molded products, the market shares of Yokogawa Precision and Jinsheng New Materials, key enterprises in the injection molding products industry, in 2021 will only account for 0.11% and 0.05% respectively. As the industry continues to develop in the future, corporate production efficiency continues to improve, the industrial structure is optimized and costs are effectively controlled, the profit margins of the injection molding products industry will further grow.

4. Development trend: Green and environmental protection attributes are more prominent, and the supply and demand of precision injection molded products will grow rapidly.

With the improvement of the level of national economic development and the continuous upgrading of social consumption, the rapid development of express delivery, takeout, construction, automobiles, household appliances, packaging, consumer electronics, medical equipment and other industries has promoted the continuous growth of plastic consumption and the environmental pollution caused by plastics. The problem is getting worse day by day. To this end, the country has issued multiple policies to accelerate the transformation of injection molded products into green products. In the future, with the advancement of the "plastic ban and restriction" and "double carbon action" policies and the enhancement of social environmental awareness, the green and environmentally friendly attributes of injection molded products will become more prominent. Due to the continuous improvement of industrial level, downstream customers' requirements for injection molded products will tend to be more sophisticated and functionally diversified; at the same time, to expand the application scope and market penetration rate of my country's injection molded products in advanced manufacturing and emerging fields, injection molding products companies are required to strengthen R&D strength, achieving innovative breakthroughs in production technology and product technology, and taking market demand as the guide to improve product quality, functionality and precision. Under this situation, the supply and demand sides of my country's precision injection molded products will grow simultaneously and rapidly in the future.

1. Development environment: favorable policies and economic growth, the industry has broad prospects for development

Injection molded products refer to products that are heated, plasticized, and melted by an injection molding machine, and then injected into the cavity of the mold for molding. After cooling, the melt is solidified, and then demoulded. Plastic injection molding machines have a wide variety of injection molded products and a wide range of applications. Especially in the textile equipment and automobile manufacturing industries, there are various shapes of injection molded products used as accessories. Medical equipment, cultural and educational supplies, and various containers, turnover boxes, and shoes that can be seen everywhere in people's daily lives. There are also various complex injection molded structural parts, functional parts and special-purpose precision parts. Injection molded products are widely used in all aspects of the national economy such as transportation, packaging, postal and telecommunications, communications, construction, home appliances, computers, aerospace and national defense cutting-edge. field, has become an indispensable means of production and consumer goods.

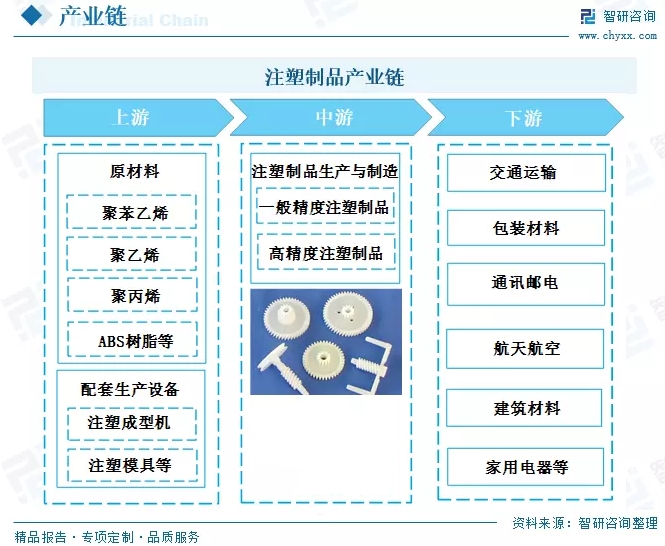

The upstream of the injection molding products industry mainly includes raw materials and supporting production equipment. The main raw materials are polystyrene, polyethylene, polypropylene and ABS resins. These four types of resin injection molded plastic products account for more than 80% of the total raw materials for injection molded products. Among them, polystyrene, polyethylene and polypropylene resins account for 70% of the total raw materials used. In addition, raw materials for injection molding products include: polyvinyl chloride, acrylonitrile-styrene copolymer, cellulose acetate, etc. The midstream is the production and manufacturing of injection molded products, and the downstream application fields mainly include transportation and packaging, post and telecommunications, communications, construction, home appliances, computer aerospace and defense cutting-edge industries.

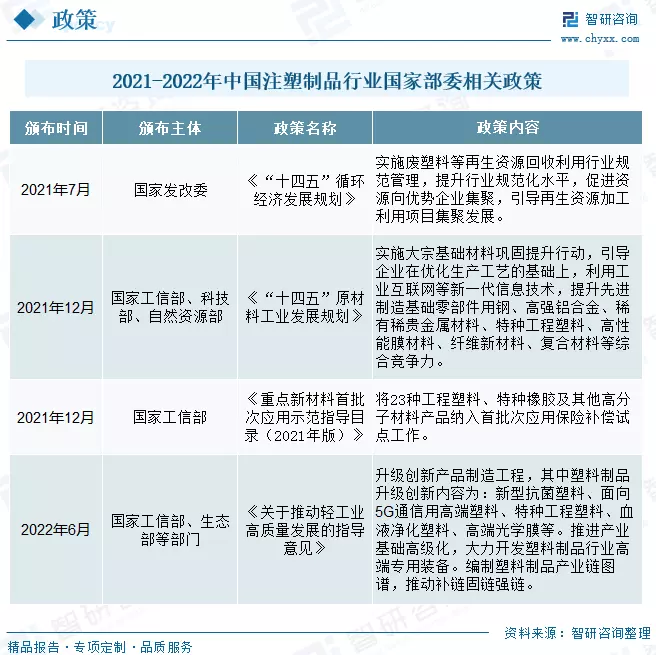

The raw material industry is the foundation of the real economy, a basic industry that supports the development of the national economy and a key area for winning international competitive advantage. It is the main force in the reconstruction of the industrial base and the main battlefield for industrial green development. Among them, the plastic industry is one of the pillar industries of my country's light industry and is closely related to my country's national economy. In order to improve the quality and efficiency of the development of the raw material industry, promote the green, sustainable and high-quality development of the plastics processing industry, achieve collaborative innovation in the industrial chain, and participate in the domestic and international dual cycles at a higher level to accelerate the pace of the industry from large to strong, in recent years the country has successively issued a number of Ministry of Industry and Information Technology supports the development of domestic injection molding products industry. The "14th Five-Year Plan for the Development of Raw Materials Industry" jointly issued by the Ministry of Industry and Information Technology, the Ministry of Science and Technology, and the Ministry of Natural Resources in December 2021 proposed that actions to consolidate and improve bulk basic materials should be implemented to guide enterprises to optimize production processes. Utilize next-generation information technology such as the Industrial Internet to enhance the comprehensive competitiveness of advanced manufacturing basic components such as steel, high-strength aluminum alloys, rare and precious metal materials, special engineering plastics, high-performance membrane materials, new fiber materials, and composite materials. At the same time, the Ministry of Industry and Information Technology released the "Guidance Catalog for the First Batch Application Demonstration of Key New Materials (2021 Edition)", which included 23 types of engineering plastics, special rubber and other polymer material products into the first batch of application insurance compensation pilot projects. In June 2022, the "Guiding Opinions on Promoting the High-Quality Development of Light Industry" jointly issued by the Ministry of Industry and Information Technology, the Ministry of Ecology and other departments proposed to upgrade innovative new antibacterial plastics, high-end plastics for 5G communications, special engineering plastics, blood purification plastics, For plastic products such as high-end optical films, we will promote the upgrading of the industrial base, vigorously develop high-end special equipment for the plastic products industry, compile a map of the plastic products industry chain, and promote the strengthening of the chain and the strengthening of the chain. Favorable policies provide a stable development environment for my country's injection molding products industry.

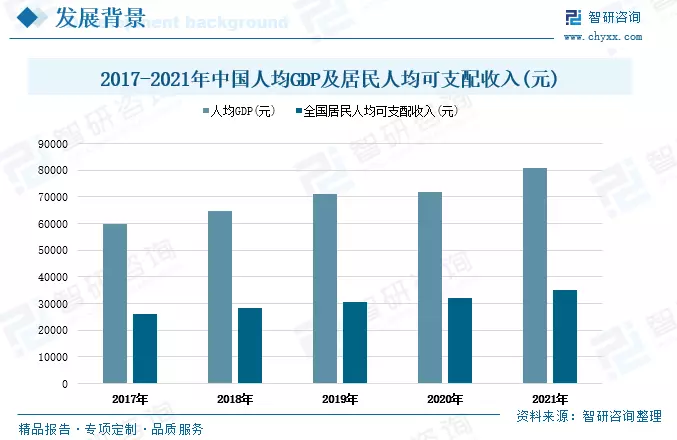

With the continuous development of China's economy, China's per capita GDP has continued to rise in recent years, residents' per capita disposable income has increased, and people's consumption power and living standards have significantly improved. According to statistics from the National Bureau of Statistics, China's per capita GDP and per capita disposable income of residents showed an upward trend year by year from 2017 to 2021. In 2021, China's per capita GDP reached 81,000 yuan, a year-on-year increase of 12.7%. The per capita disposable income of Chinese residents in 2021 is 35,100 yuan, a year-on-year increase of 9.13%, and an increase of 9,154 yuan compared to 2017. As the trend of economic development in the future remains unchanged, social consumption will continue to upgrade, which will provide a good development environment for China's injection molded products industry, and at the same time drive the application fields of injection molded products such as agriculture, fishery, packaging, transportation, electrical, chemical industry, The development of industries such as construction, aviation, national defense, medical equipment, and daily cosmetics has driven the continued growth of demand for injection molded products, providing broad development prospects for China's injection molded products industry.

Related reports: "2023-2029 China Injection Molding Products Industry Development Model Analysis and Future Prospects Planning Report" released by Zhiyan Consulting

2. Development status: The rapid development of the downstream field has driven the continued expansion of the market size of injection molded products.

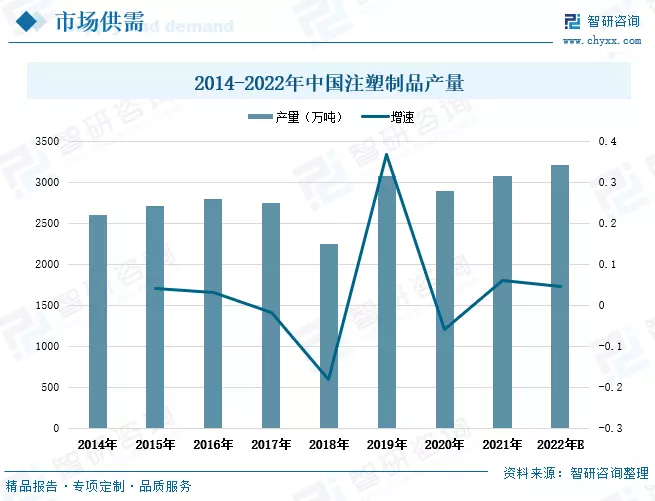

Compared with metal, stone, and wood, plastic products have the advantages of low cost and strong plasticity. They are widely used in the national economy. The plastics industry occupies an extremely important position in the world today. Over the years, the production of plastic products has developed at a high speed around the world. . At present, my country's plastic product output ranks at the forefront of the world rankings, and the output of many plastic products has ranked first in the world. my country has become a major producer of plastic products in the world, among which injection molding is an important production method of plastic products. In the current engineering plastics industry 80% of them are injection molded. Injection molding is one of the important production processes in my country's plastic products industry. As the industry ushered in rapid development, the number of companies entering the industry increased, investment in production line construction increased, the industrial structure was gradually optimized and upgraded, and production capacity continued to increase. In recent years, the output of injection molded products across the country has continued to increase. increase. In 2021, the national output of injection molded products will reach 30.72 million tons, a growth rate of 6.11%. Compared with the national output of injection molded products in 2014, it has increased by 4.71 million tons.

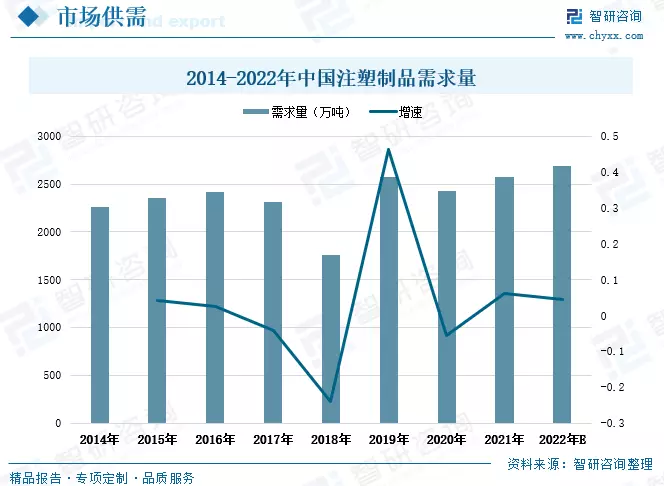

With the continuous development of the plastics industry, injection molded products have become increasingly popular and are now widely used in automobiles, construction, home appliances, food, medicine and other industries. Among them, general precision injection molded products are relatively large in size and have a long production cycle. They often involve secondary complex processing and are used in building materials, auto parts, household appliances, toys, large medical equipment and other daily necessities. High-precision injection molded products require the use of high-precision molds. They are often fast-moving products and adopt large-scale quantitative production. They are mainly used in medical disposable products, packaging and packaging products, consumer electronics, etc. Benefiting from the continuous expansion of the development scale of downstream application fields, the demand for injection molded products is growing day by day. At the same time, the production technology level of injection molded products continues to improve and product functions are increased, and they are applied to emerging manufacturing industries such as new energy vehicles, medical equipment, and intelligent manufacturing. Bringing new market demand space, the demand for injection molded products across the country continues to expand. According to statistical data, between 2014 and 2021, the national demand for injection molded products increased from 22.66 million tons to 25.77 million tons, with a growth rate of 3.11 million tons during the period. With the recovery of the social economy and the good prevention and control of the epidemic situation, the national injection molded products market will pick up in 2021, with a demand growth rate of 6.05%, an increase of nearly 12 percentage points compared to the previous year.

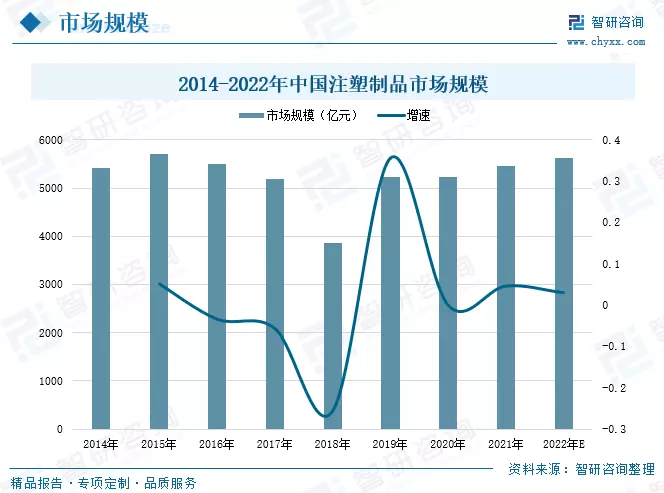

my country's injection molding products industry started in the late 1990s and has gone through five stages: technology introduction, professional market introduction, technology improvement, technology application, and use in various industries. At present, the domestic injection molding products industry is in a stage of rapid development. The application scope of injection molding products covers real estate, automobiles, household appliances, packaging, consumer electronics, medical equipment and other fields. The huge downstream industry provides strong support for the development of my country's injection molding products industry. Benefiting from the development and growth of real estate, automobiles, household appliances, packaging, consumer electronics, medical equipment and other industries, the market demand for injection molded products has grown steadily. At the same time, due to further innovative breakthroughs in the performance of domestic injection molded products, the market penetration rate of injection molded products continues to increase, and they have begun to be applied to advanced emerging industries such as aerospace, new energy, and smart homes. The market space for my country's injection molded products continues to expand. According to statistical data, my country's injection molding products market size has increased from 542.6 billion yuan in 2014 to 546.3 billion yuan in 2021, with the market size increasing by 3.7 billion yuan during the period. The growth rate of the national injection molding products market in 2021 is 4.56%. Based on the current good development situation, it is expected that the domestic injection molding products market will achieve further growth in 2022, reaching 562.4 billion yuan.

The market price of the injection molded products industry is mainly affected by various factors such as market supply and demand, raw material prices, labor costs, sales prices, mold precision, product structure, and market competition. Therefore, the market price of injection molded products across the country has fluctuated in recent years. Generally speaking, when new downstream products are in the introduction period, the sales price of injection molded products is higher, and the industry's profit margin is larger. In recent years, the average market price of the domestic injection molding products industry has shown an overall fluctuating downward trend. The average market price of injection molding products in 2021 is 21,199 yuan/ton, which is a decrease of 2,746 yuan per ton compared with the average market price of injection molding products in 2014.

3. Market structure: Industry concentration is extremely low, and the operating situation of key enterprises is improving.

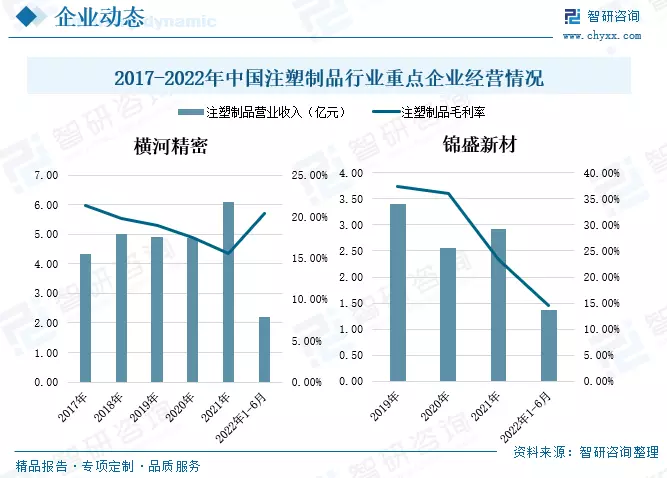

Judging from the distribution of the market competition pattern, the current market pattern of my country's injection molding products industry is fragmented, the industry concentration is extremely low, there is no industry leader yet, and the competition among enterprises is fierce. Calculated based on the income caliber of injection molded products, the market shares of Yokogawa Precision and Jinsheng New Materials, key enterprises in the injection molding products industry, in 2021 will only account for 0.11% and 0.05% respectively.

Judging from the operating conditions of key enterprises in the industry, Yokogawa Precision focuses on the R&D and manufacturing of precision molds and precision components. Its existing products include precision gears and gearboxes, precision structural parts, cooling fans, all-plastic tailgates, all-plastic Engine hoods, fuel door actuators, etc. are widely used in smart home appliances, automotive smart cockpits, lightweight applications of automotive engineering plastics, etc. In recent years, the company's operating income from injection molding products has shown an overall growth trend, especially in 2021. The operating income from injection molding products reached 610 million yuan, a year-on-year increase of 25.3%. From 2017 to 2021, the company's gross profit margin for injection molded products fell from 21.36% to 15.53%. In the first half of 2022, the gross profit margin rebounded and rose to 20.38%.

Jinsheng New Materials is mainly engaged in the research and development, production and sales of cosmetic plastic packaging containers. Its main products include cream bottle series products and lotion bottle series products. The company has rich product design, technology research and development and process innovation in acrylic (PMMA) cosmetic packaging containers. Experience, is a well-known cosmetic packaging container supplier in the industry. Affected by the epidemic situation, rising raw material prices, increased labor costs, fluctuations in market demand, etc., the company's injection molding products operating income fell to 256 million yuan in 2020, a year-on-year decrease of 25%; as the epidemic is under control, the company actively responds to business operations Adjustments have been made, and the operating income of injection molded products has rebounded to 291 million yuan in 2021. From 2019 to the first half of 2022, the company's gross profit margin of injection molded products has declined year after year, from 37.27% to 14.55%. As the industry continues to develop in the future, corporate production efficiency continues to improve, the industrial structure is optimized and costs are effectively controlled, the profit margins of the injection molding products industry will further grow.

4. Development trend: Green and environmental protection attributes are more prominent, and the supply and demand of precision injection molded products will grow rapidly.

1. The green and environmentally friendly attributes of injection molded products will be more prominent

With the improvement of the level of national economic development and the continuous upgrading of social consumption, the rapid development of express delivery, takeaway, real estate, automobiles, household appliances, packaging, consumer electronics, medical equipment and other industries has promoted the continuous growth of plastic consumption and the environmental pollution problems caused by plastics. Increasingly. To this end, the country has issued multiple policies to accelerate the transformation of injection molded products into green products. Among them, the "Biodegradable Drinking Straws" and "Biodegradable Plastics and Products Degradation Performance and Labeling Requirements" formulated and issued by the National Standardization Management Committee of the State Administration for Market Regulation, two national standards in the field of degradable plastics will be effective from June 1, 2022 officially implemented on the day. On June 17, the Ministry of Industry and Information Technology, the Ministry of Human Resources and Social Security, the Ministry of Ecology and Environment, the Ministry of Commerce, and the State Administration for Market Regulation jointly issued the "Guiding Opinions on Promoting the High-Quality Development of Light Industry" which clearly stated that the development of new biomass materials and all-biotechnology Low-carbon technology development projects for materials such as degradable mulch films and green product consumption of degradable material products. In the future, as the "plastic ban and restriction" and "double carbon action" policies continue to advance and social awareness of environmental protection increases, the green and environmentally friendly attributes of injection molded products will become more prominent.

2. The supply and demand of precision injection molded products are growing rapidly simultaneously.

The plastic processing industry is an emerging manufacturing industry with plastic processing and molding as its core and integrating synthetic resins, additives, modified plastics, recycled plastics, plastic machinery and molds, intelligent systems and other industries. It is the mainstay of the high-end polymer new materials industry. It is not only an advanced manufacturing industry in my country's modern industrial system, but also a people's livelihood industry. According to national policy trends and development plans, the injection molded products industry will move in the direction of "functionality, lightweight, precision, ecology, and intelligence" in the future. With the continuous improvement of industrial level, downstream customers' requirements for injection molded products will tend to be more precise and functionally diversified; at the same time, in order to expand the application scope and market penetration rate of my country's injection molded products in advanced manufacturing and emerging fields, injection molding products companies are required to Strengthen R&D capabilities, achieve innovative breakthroughs in production technology and product processes, and be guided by market demand to improve product quality, functionality, and precision. Under this situation, the supply and demand for precision injection molded products in my country will grow simultaneously and rapidly in the future.

3. The market share of domestic injection molding products companies has increased

The current market competition in the injection molding products industry is fierce, with domestic companies and foreign-funded companies rushing to seize the market track. With national policy support and increased social investment, domestic injection molding products companies have increased their R&D investment, injection molding product production technology and product quality will be greatly improved, and the competitive advantages of domestic injection molding products have been enhanced; at the same time, domestic injection molding products companies have optimized their industrial structure and And the integration of industry chain resources will further achieve positive results in cost control, and the price advantage will gradually become more prominent. In the future, the market share of domestic injection molding products companies will increase, and the market concentration of the industry will show an upward trend.

The above data and information can be referred to the "2023-2029 China Injection Molding Products Industry Development Model Analysis and Future Prospects Planning Report" released by Zhiyan Consulting. Zhiyan Consulting is a comprehensive provider of information and intelligence in the field of industrial consulting in China. The company takes "using information to drive industrial development and empower corporate investment decisions" as its brand concept. Provide professional industrial consulting services to enterprises. The main services include high-quality industry research reports, special customization, monthly special topics, feasibility study reports, business plans, industrial planning, etc. Provides regular reports and customized data such as weekly/monthly/quarterly/annual reports, covering policy monitoring, corporate dynamics, industry data, product price changes, investment and financing overview, market opportunities and risk analysis, etc.