The secondary processing technology of plastic products includes: oil spraying, silk screen printing, pad printing, bronzing, laser engraving, assembly, etc. Oil spraying is to use manual or automatic spraying equipment to spray paint on the plastic surface or inner surface; silk screen printing is to print on a specific position on the surface of plastic products through screen plates and screen printing machines, and pad printing can pass through steel plates and pad printing machines. The required text or pattern; hot stamping is to cover the metal part of the hot stamping paper on the surface of the product through a flat or curved hot stamping machine under high temperature and pressure, so that the surface is covered with metal characters or patterns; laser engraving is laser engraving processing is Using numerical control technology as the basis, laser as the processing medium, the processing materials are instantly melted and gasified under the laser irradiation to achieve the purpose of processing.

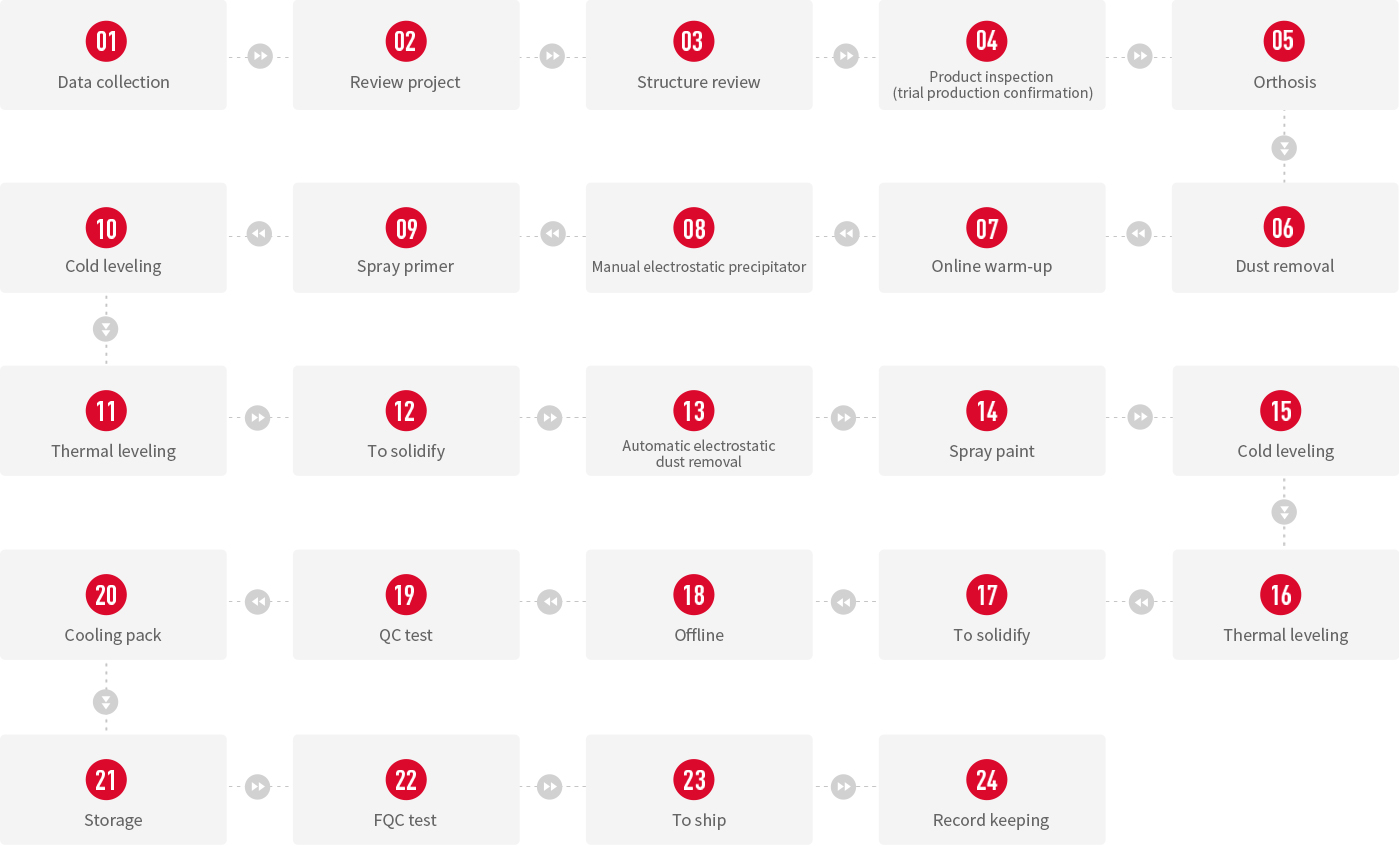

Data collection

Review project

Structure review

Product inspection (trial production confirmation)

Orthosis

Dust removal

Online warm-up

Manual electrostatic precipitator

Spray primer

Cold leveling

Thermal leveling

To solidify

Automatic electrostatic dust removal

Spray paint

Cold leveling

Thermal leveling

To solidify

Offline

QC inspection

Cooling pack

Storage

FQC inspection

To ship

Record keeping

Monthly Production Capacity