The processing equipment corresponding to the plastic injection mold is a plastic injection molding machine. The plastic is first heated and melted in the heating barrel at the bottom of the injection machine, and then pushed by the screw or plunger of the injection machine, it enters the mold cavity through the nozzle of the injection machine and the gating system of the mold. The plastic is cooled and hardened to form, and the product is demolded. The injection molding processing method is usually only suitable for the production of thermoplastic products. The plastic products produced by the injection molding process are very extensive, ranging from daily necessities to various complex machinery, electrical appliances, and vehicle parts. It is the most widely used processing method in the production of plastic products.

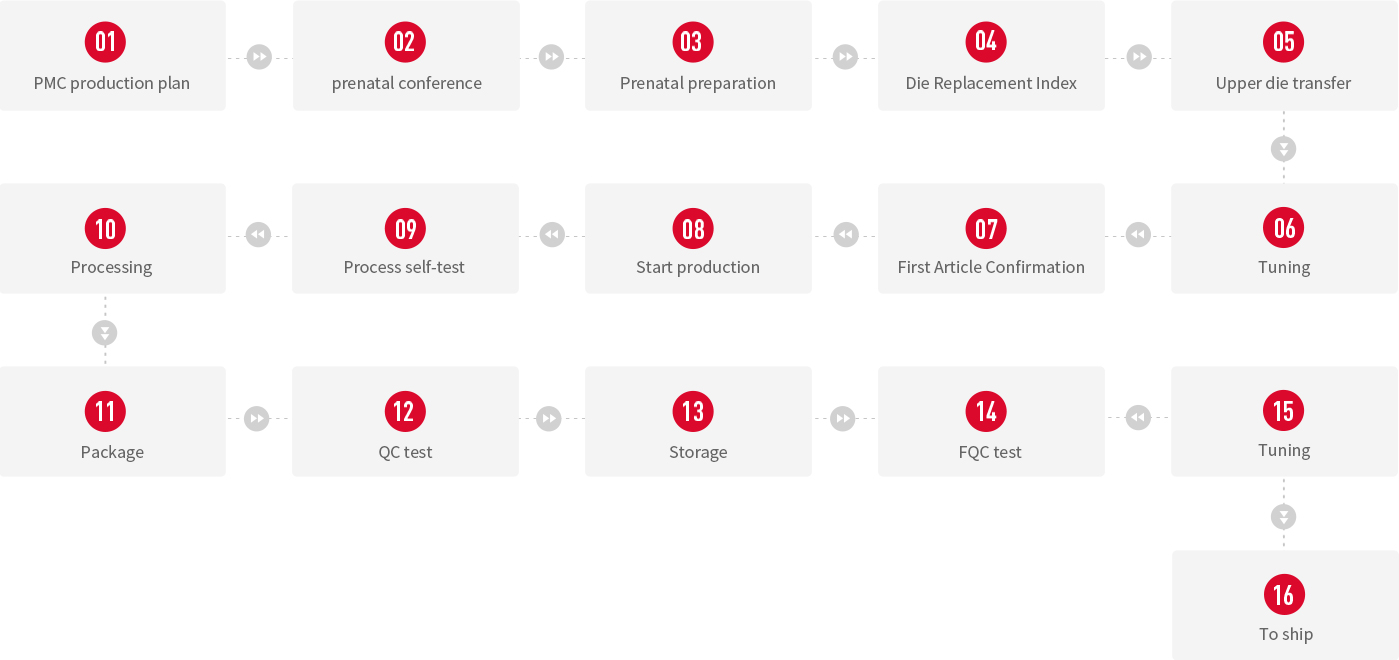

PMC production plan

Prenatal conference

Prenatal preparation

Die replacement index

Upper die transfer

Tuning

First article confirmation

Start production

Process self-test

Processing

Package

QC inspection

Storage

FQC inspection

Tuning

To ship

Monthly Manufacturing Hours