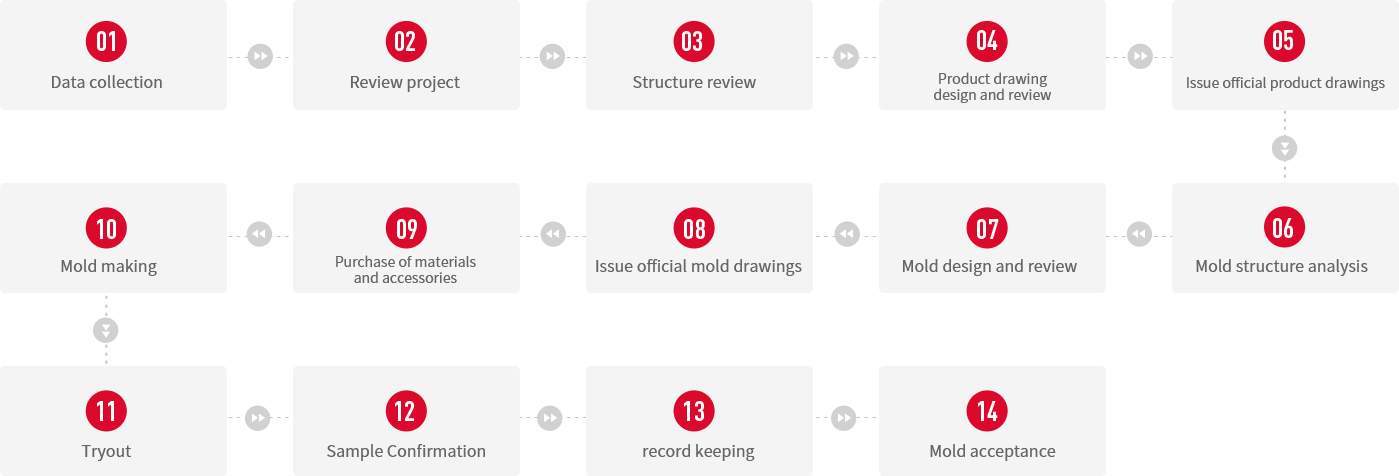

According to the different molding methods, the types of plastic processing molds corresponding to different process requirements can be divided, mainly including injection molding moulds, extrusion molding moulds, blister molding moulds, high-expansion polystyrene molding moulds, etc. Our company is mainly engaged in plastic injection (plastic) molding molds, which are the most commonly used molding molds in the production of thermoplastic parts. Its structure is usually composed of molding parts, pouring system, guide parts, ejection mechanism, temperature adjustment system, exhaust system, support parts and other parts. The manufacturing materials usually use plastic mold steel modules, and the commonly used materials are mainly carbon structural steel, carbon tool steel, alloy tool steel, high-speed steel, etc.