2023-10-21

2023-10-21

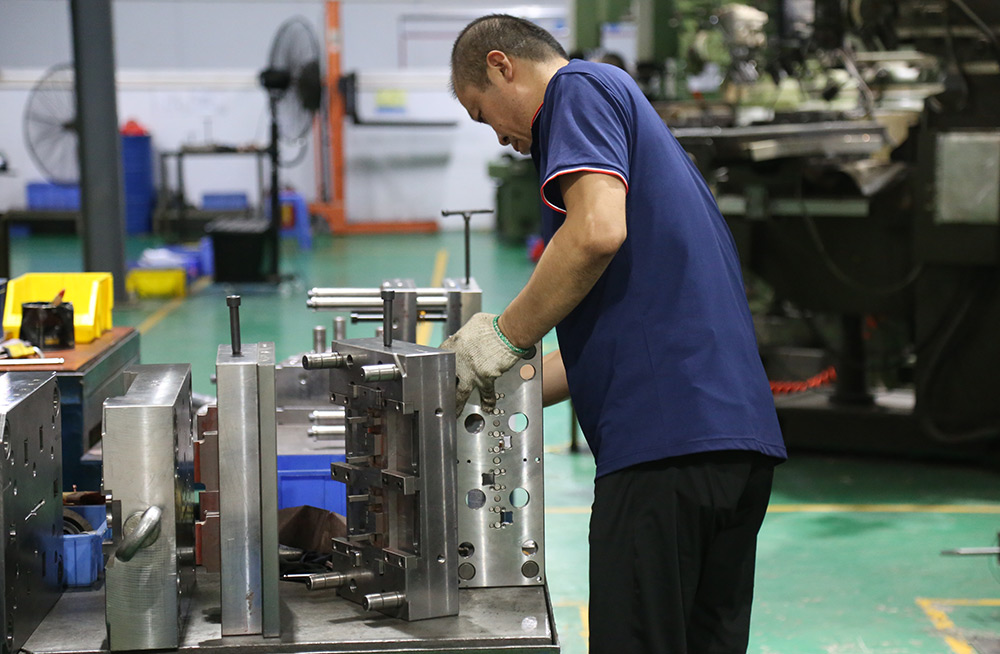

1. Development status:

The plastics industry is one of the pillar industries of my country's light industry and is closely related to my country's national economy. With the rapid development of my country's economy in recent years, the demand for injection molded products in downstream fields such as automobiles, home appliances, medical health, consumer electronics, daily necessities, and packaging has continued to increase. At the same time, with the development of polymer material technology and the emergence of high-strength new materials Development, the application fields of injection molded products have also been continuously expanded, further driving the development of my country's injection molded products industry. According to data, my country's injection molding product production capacity will be 43.75 million tons in 2022, a year-on-year increase of 0.8; output will be 31.35 million tons, a year-on-year increase of 2.7%; demand will be 26.3 million tons, a year-on-year increase of 2.4%.

In addition, the market size of my country's injection molding products industry in 2022 will be about 614.4 billion yuan, a year-on-year increase of 8.3%. From a price perspective, in recent years, the average price of my country's injection molding products industry has shown an overall trend of first falling and then rising. In 2019, it fell to the lowest value in recent years. Subsequently, with the development of the industry and the increase in upstream raw material prices, the average price of injection molding products began to rise. , the average price will increase to about 23,400 yuan/ton by 2022.

2. Challenges faced:

Although the development of the injection molding industry is generally upward, because the injection molding industry is a typical discrete process industry, its multi-model products also reflect the complex process problems of the injection molding industry. At present, most injection molding companies are facing the following difficulties:

1. The update cycle of injection molded products is shortened, and companies are under great pressure on delivery times.

2. Enterprises cannot automatically obtain the operating status of workshop equipment, cannot record equipment process parameters and data accurately in a timely manner, and cannot conduct retrospective analysis of problems.

3. There are many cases of changing orders and inserting orders, but scheduling and changes are very difficult.

4. The information at the production site lacks synergy, resulting in reduced efficiency of production operations.

5. The machine directly determines the production capacity, and the schedule goes directly to the machine.

Generally speaking, the injection molding industry also faces the following challenges:

1. Mold production supply and demand imbalance: There are many domestic mold companies, but the production volume of most companies cannot meet market demand. The domestic market satisfaction rate for domestic injection molds is less than 74%, and the satisfaction rate for large precision molds is even lower. This contradiction between supply and demand limits the development of the injection molding industry to a certain extent.

2. Lagging technological level: Although the technology of some domestic enterprises has reached or is close to the international level, in general, the molds produced by domestic enterprises are still far behind foreign enterprises in terms of accuracy, production cycle, service life and other indicators. The backwardness of the overall technical level limits the further development of the injection molding industry.

3. Insufficient innovation capabilities: Most enterprises have a low proportion of technical personnel, insufficient innovation capabilities, low investment in scientific research and development, and backward management systems. This makes the injection molding industry make slow progress in the development of new technologies and new products, and cannot keep up with market changes and needs in a timely manner.

4. Unreasonable industrial structure: The industrial structure of the injection molding industry is not balanced enough, and there is a problem of unbalanced industrial development. Although the products of individual companies have reached or are close to the international advanced level, in general, the molds produced by domestic companies are still far behind foreign companies in terms of accuracy and service life.

5. Low degree of informatization: With the development of information technology, information technology has also begun to be widely used in industrial production to improve production efficiency and product quality. However, many injection molding companies currently have a relatively low degree of informatization and are unable to meet the needs of modern mass production.

6. Increased pressure on environmental protection: With the improvement of environmental awareness, society’s environmental protection requirements for the manufacturing industry are also getting higher and higher. As a part of the manufacturing industry, the injection molding industry needs to adopt more environmentally friendly production methods and technologies to comply with national environmental protection regulations and market demand. This will increase costs and challenges for the injection molding industry.

7. Fierce market competition: Competition in the injection molding market is fierce, and there are price wars and other unhealthy competition phenomena between companies. This makes it difficult for enterprises to obtain reasonable profits and development space, and is not conducive to the healthy development of the industry.

8. Diversified customer demands: With the diversification of market demands, injection molded products also need to be more personalized, functional and environmentally friendly. This requires enterprises to have strong R&D capabilities and technical levels to adapt to market changes and needs.